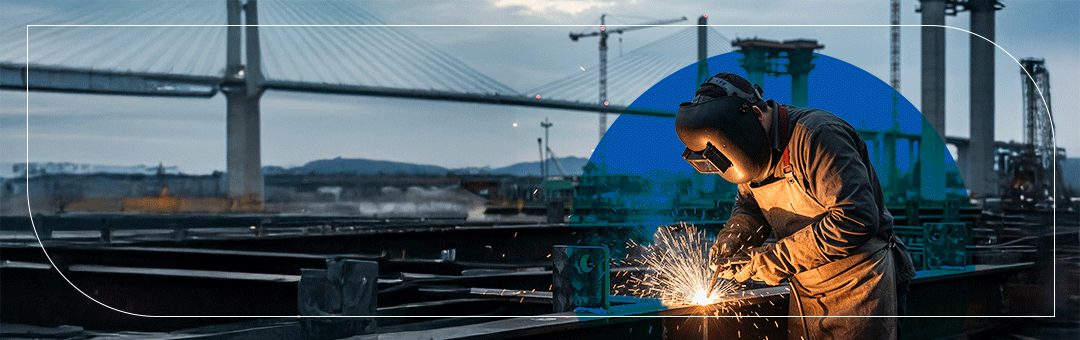

Metal Fabrication for Bridges & Infrastructure Projects

Metal Fabrication for Bridges & Infrastructure Projects

Metal fabrication plays a pivotal role in the development of bridges and large-scale infrastructure projects, forming the backbone of modern transportation and urban connectivity. From highways and flyovers to rail bridges and pedestrian crossings, fabricated metal components ensure strength, precision, and long-term structural reliability. As infrastructure demands grow in scale and complexity, advanced metal fabrication has become indispensable for delivering safe, durable solutions.

Role of Metal Fabrication in Infrastructure

Metal fabrication involves cutting, bending, welding, and assembling metal to create engineered components that meet strict design and performance requirements. In bridge and infrastructure projects, fabricated steel elements are used for load-bearing frameworks, girders, trusses, decks, railings, and support systems. These components are manufactured under controlled conditions, ensuring dimensional accuracy and consistent quality.

Key Advantages of Metal Fabrication

- Structural Strength and Load Capacity

Fabricated steel offers a high strength-to-weight ratio, enabling bridges to support heavy traffic loads while maintaining structural stability. - Precision Engineering

Computer-aided design and automated fabrication processes ensure accuracy, reducing errors during on-site assembly and installation. - Speed of Construction

Prefabricated metal components allow faster erection at project sites, minimising construction timelines and traffic disruptions. - Design Flexibility

Metal fabrication supports complex geometries and customised designs, meeting both functional and aesthetic requirements of modern infrastructure.

Applications in Bridges and Infrastructure

Metal fabrication is extensively used across various infrastructure segments. In bridge construction, fabricated steel is used for main girders, cross beams, bearings, expansion joints, and handrails. In highways and urban infrastructure, it supports flyovers, metro viaducts, elevated corridors, foot overbridges, and industrial structures. Fabricated components are also critical for ancillary systems, including lighting poles, sign gantries, drainage supports, and safety barriers.

Durability and Safety Considerations

Infrastructure projects demand materials that can withstand extreme loads, vibrations, and environmental exposure. Fabricated metal components are often treated with galvanisation, protective coatings, or specialised paints to resist corrosion, moisture, and temperature variations. Strict adherence to national and international standards ensures safety, fatigue resistance, and long service life, reducing the risk of structural failure.

Sustainability and Cost Efficiency

Metal fabrication supports sustainable construction practices. Steel is recyclable, reducing environmental impact and promoting resource efficiency. Factory-controlled fabrication minimises material wastage, while long-lasting components reduce maintenance and lifecycle costs. Faster construction also translates into economic savings and reduced social inconvenience.

Quality Control and Compliance

Robust quality assurance processes are integral to metal fabrication for infrastructure. Non-destructive testing, dimensional inspections, and material certifications ensure compliance with project specifications and regulatory standards. This focus on quality enhances reliability and builds public confidence in critical infrastructure assets.

At Pinax Steel, metal fabrication is driven by a commitment to engineering excellence, quality assurance, and long-term performance. With advanced fabrication capabilities, stringent quality control processes, and adherence to national and international standards, Pinax Steel delivers reliable solutions for critical bridges and infrastructure projects.

By combining precision manufacturing with durable materials and sustainable practices, Pinax Steel continues to support the development of resilient transportation networks and infrastructure assets. Each fabricated component reflects the brand’s focus on safety, strength, and efficiency—contributing to infrastructure that stands strong, performs consistently, and serves generations to come.

If you are interested in combining strength with design flexibility, steel metal fabrication is a key contributor to advanced shipbuilding. Reading it out…