Perforated Cable Trays – How and Why?

Perforated Cable Trays – How and Why?

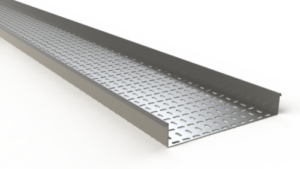

In any major wiring project, cable trays act as mechanical support providing protection for installed wires. Cable Trays are usually used when there is a multiple wire arrangement for power and signal cables. When the load is heavy the wires can overheat, particularly if the cabling system is enclosed. Another risk is moisture buildup. Think of electricity running through the system like a person running with a jacket on. A fully enclosed jacket makes you feel hotter as your body heat and sweat get trapped. Since overheating can be hazardous, natural cooling becomes imperative. This is done by perforation.

Perforation is a process where the cable tray manufacturer punctures a set of holes in the tray to allow ventilation without diminishing the primary purpose of providing support. If we continue our analogy, having holes in your jacket allows you to cool down and the sweat to evaporate. The perforation on the cable trays acts as a mechanism that provides sufficient airing while the electrical wires are running. Perforated cable tray systems come with required accessories that are needed for installation and further protection. These include slotted angles, clips, perforated cable tray covers, lids, etc. These ensure that the setup for the wire arrangement remains neat and sturdy.

Pic- Solid Bottom Cable Tray.jpg

How are the cable trays perforated?

Perforated cable tray manufacturers make use of the latest production technologies in order to ensure that the holes are punctured either in the side rails or on the bottom of the cable trays with precision.

Pic- Bottom of the Cable Trays .jpg

Perforation is done during the finishing stage of manufacturing. For Galvanized Iron (GI) trays, this is usually post-galvanization and cutting. The sheets are placed in a high-speed punching system, so that holes can be precisely pinched as dictated by design and ventilation requirements. Different holes sizes, shapes and patterns can be cut. Once the punching is completed, the sheets are formed into trays of required dimension. The tray system includes perforated cable tray covers. This is because keeping them open from the top might make the wires prone to moisture and other damage. Perforated cable tray covers serve the purpose of creating a complete envelope for the wires. Once the arrangement for the wires is set, the cover is slid on the top. This seals the electric wires within the trays creating a protected setup. It is not essential for covers to be perforated as the ventilation takes place from the holes on the side rails or beneath the surface of the trays.

Why are cable trays perforated?

As any perforated cable tray supplier will point out sufficient ventilation is required in any electrical cabling system to minimize chances of accidental fire. In a large cable network constant monitoring is not always possible, and perforated trays are the first line of defense to prevent temperature rise. Apart from the risks of heat build-up, power cable systems also run the risk of moisture build-up. This is particularly true for systems that are exposed to external elements. In traditional conduit or even conventional cable trays, this moisture may accumulate and eventually damage the wire insulation. Perforated trays allow the moisture to evaporate before any damage can be caused. Finally, perforation allows limited visibility which may prove critical in some cases as any electrical sparks can be seen.

Pic- Perforated Cable Tray Covers .jpg

Demand for perforated cable trays:

There has been a consistent demand for cable trays in the infrastructural market. Many production units have established themselves solely as perforated cable tray manufacturers. According to the analyst forecasts, the global cable tray market is expected to grow at a CAGR of 9.33% between the years 2018 and 2022. Galvanized Iron (GI) perforated cable trays are expected to remain a major segment due to their several advantages and economy.

Pinax Steel is a leading manufacturer of cable trays with an established reputation for cable tray systems of international quality standards. We employ the best technology for galvanizing, perforation, and fabrication to ensure customer satisfaction over the years. To know more about us, our manufacturing processes, and customer services click here